Hooked on BOM? Here's a bold claim: traditional manufacturing methods are out! The future? Dual...

Modernizing BOM Management with CPQ

In the realm of manufacturing, the static Bill of Materials (BOM) is becoming a relic of the past. As customer demands evolve and product customization becomes the norm, relying on unchanging BOMs can lead to production inefficiencies, costly errors, and misaligned teams. The future lies in adopting dual-BOM management within Configure, Price, Quote (CPQ) systems—a strategy that not only aligns sales and production but also propels manufacturers into a new era of efficiency and responsiveness.

The Pitfalls of Static BOMs

Traditionally, manufacturers have depended on static BOMs to outline the components and materials required for product assembly. While this approach sufficed in an era of mass production with limited variation, it falls short in today's market, where customers expect products tailored to their specific needs. Static BOMs struggle to accommodate the dynamic nature of customized orders, leading to:

- Production Delays: Inflexible BOMs can't swiftly adapt to unique customer specifications, causing hold-ups as production teams scramble to adjust.

- Errors and Rework: Misalignment between what was sold and what can be produced results in mistakes, necessitating costly rework and material waste.

- Frustrated Teams: Discrepancies between sales promises and production capabilities create friction among departments, undermining morale and collaboration.

Embracing Dual-BOM Management with CPQ

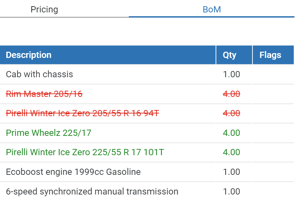

Enter dual-BOM management—a transformative approach that distinguishes between the Sales BOM (SBOM) and the Manufacturing BOM (MBOM). Within a CPQ system, this dual structure ensures that both sales and production teams operate from synchronized, up-to-date information. Here's how it revolutionizes manufacturing:

- Real-Time Synchronization: As sales representatives configure products based on customer preferences, the CPQ system concurrently updates the MBOM. This real-time alignment eradicates miscommunication, ensuring that production is always prepared to meet specific customer requirements.

- Enhanced Flexibility: Dual-BOM management allows manufacturers to swiftly adapt to changes in customer demands without overhauling the entire BOM structure. This flexibility is crucial for staying competitive in a market that values customization.

- Improved Accuracy: With both BOMs managed simultaneously, the likelihood of errors diminishes. Sales configurations are immediately validated against manufacturing capabilities, ensuring feasibility and reducing the risk of costly mistakes.

The cpq.se Perspective: Implementing Dual-BOM Management

At cpq.se, we've witnessed firsthand the transformative power of integrating dual-BOM management within CPQ systems. Our collaboration with clients like HMF, a leading producer of truck-mounted cranes, showcases the tangible benefits of this approach. By adopting dual-BOM management, HMF streamlined their operations, ensuring that complex product configurations were accurately translated from sales to production, thereby reducing errors and accelerating delivery times. For a deeper dive into this topic, you can read our article on Why Dual BOM Management in CPQ is The Future of Manufacturing.

Key Benefits Observed:

- Seamless Data Integration: By connecting CPQ systems with existing ERP, CRM, and PLM platforms, manufacturers achieve a unified data environment. This integration ensures that all departments access consistent, real-time information, enhancing decision-making and operational efficiency. Learn more in our post on How CPQ Data Integration Can Transform Manufacturing Efficiency.

- Accelerated Production Cycles: With synchronized BOMs, the transition from order placement to manufacturing is expedited. This agility allows manufacturers to meet tight deadlines and respond promptly to market demands.

- Enhanced Customer Satisfaction: Accurate configurations and timely deliveries lead to happier customers. When clients receive products that precisely match their specifications without delays, it fosters trust and encourages repeat business.

The shift from static to dynamic, dual-BOM management within CPQ systems is not just a technological upgrade—it's a strategic imperative for manufacturers aiming to thrive in a customer-centric market. By ensuring alignment between sales and production, manufacturers can reduce errors, improve efficiency, and deliver customized products with confidence. At cpq.se, we're committed to guiding businesses through this transformation, leveraging our expertise to implement solutions that drive success.

To explore how dual-BOM management can revolutionize your manufacturing processes, we invite you to read more about our approach and success stories on our blog: Optimizing Sales and Production with Dual-BOM and CPQ Automation.

For a personalized discussion on implementing CPQ solutions tailored to your needs, consider scheduling a virtual coffee with Magnus or Patrik at cpq.se.