Full automation in CPQ (Configure, Price, Quote) systems has been an aspirational goal for years....

The Role of Logic Off in Modern CPQ: Balancing Automation with Flexibility

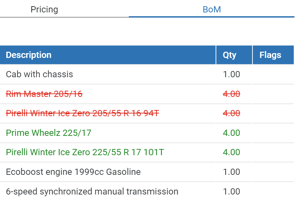

CPQ (Configure, Price, Quote) systems are often designed with a clear goal: automate every step of the configuration process to deliver error-free quotes and a complete bill of materials (BOM). But for many manufacturers, this vision collides with reality. No matter how robust a CPQ system’s logic is, there will always be scenarios where rules and constraints don’t apply.

Enter the concept of “logic off.” For organizations managing complex products or unique customer demands, the ability to bypass certain CPQ rules temporarily is essential. This isn’t about breaking the system but rather enhancing its flexibility to handle exceptions. By intentionally incorporating structured manual adjustments—or “logic off” workflows—companies can make their CPQ systems more versatile and effective.

Why “Logic Off” Matters in CPQ

CPQ systems thrive on predefined rules and constraints, but these systems can’t always account for the unpredictable. For many manufacturers, 70-80% of a configuration might be handled by automation, while the remaining work requires manual intervention. This “logic off” capability is critical for:

- Managing Unique Scenarios: Customer-specific agreements, one-off product variations, or custom components often require deviations from standard CPQ logic.

- Dynamic Cost Adjustments: Fluctuating material or labor costs may necessitate updates that weren’t anticipated during the initial configuration.

- Post-Configuration Refinements: Some organizations need to fine-tune their BOM or pricing after the initial CPQ process to meet production or customer needs.

By incorporating “logic off” into CPQ workflows, manufacturers can address these needs without compromising the integrity of their systems.

Structured Manual Adjustments: The Backbone of “Logic Off”

The concept of “logic off” isn’t about abandoning automation—it’s about creating controlled flexibility. When implemented thoughtfully, manual adjustments can complement automated workflows rather than disrupt them.

Here’s how structured manual adjustments can enhance your CPQ process:

- Predefined Manual Options: Allow users to adjust certain elements—like costs or quantities—within predefined limits, ensuring consistency and accuracy.

- Integrated Costing Tools: Embedding tools for manual cost updates within the CPQ system avoids reliance on external spreadsheets or disconnected processes.

- Read-Only Attributes: Locking key attributes while allowing manual changes to others helps preserve data integrity.

These adjustments ensure that “logic off” workflows are predictable, manageable, and efficient.

When to Use “Logic Off” in CPQ

Not every situation calls for bypassing CPQ logic. The key is knowing when and where to allow manual interventions. Here are some scenarios where “logic off” can be most valuable:

- Prototype or Custom Builds: For products that don’t follow standard configurations, manual inputs can ensure the BOM and pricing reflect unique requirements.

- Customer-Driven Modifications: When clients request last-minute changes, a “logic off” workflow can quickly adapt to their needs.

- Post-Configuration Cost Updates: Adjusting costs based on real-time data—like fluctuating supplier prices—can make quotes more accurate and competitive.

Building a Hybrid CPQ Workflow

A successful CPQ system doesn’t have to choose between full automation and manual processes. Instead, it can leverage both. By incorporating “logic off” capabilities, companies can create a hybrid workflow that balances efficiency with flexibility.

To do this effectively:

- Define Clear Rules for Manual Adjustments: Determine where “logic off” is appropriate and set boundaries to maintain system integrity.

- Streamline the Process: Make manual adjustments as simple and user-friendly as possible to minimize errors.

- Integrate, Don’t Separate: Keep manual workflows within the CPQ system itself to ensure data consistency and reduce inefficiencies.

The Future of CPQ: Logic On, Logic Off, or Both?

As manufacturers face increasing product complexity and customer demands, the need for flexible CPQ systems has never been greater. While full automation remains a valuable goal, “logic off” capabilities provide the adaptability needed to handle exceptions without derailing the process.

The next evolution of CPQ is not about choosing between logic on or logic off—it’s about creating systems that can seamlessly switch between the two. This hybrid approach ensures that businesses can handle the predictable and the unpredictable with equal ease.